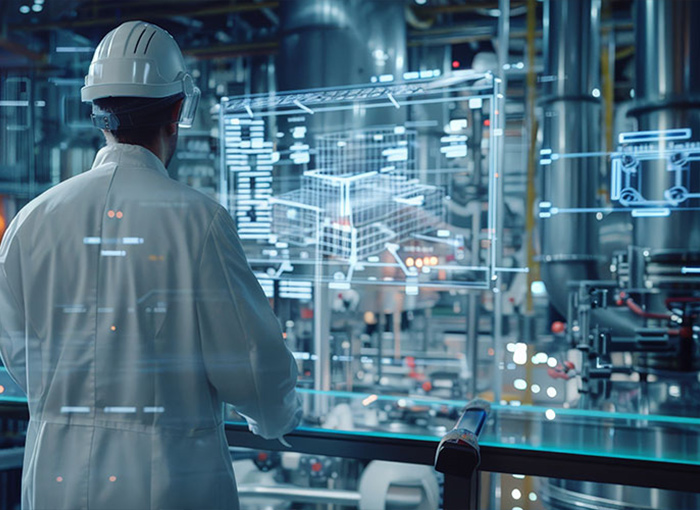

Full-Chain Production

From material processing to finished products, ensuring complete quality control.

Linhai Lezama Leisure Products Co., Ltd., established in 2013, adheres to the principles of innovation, quality, and sustainable development. We are dedicated to providing customers with premium outdoor leisure and sunshade solutions.

Our main product lines include:

Aluminium Gazebo – Features a durable retractable aluminium louver roof, independent drainage system, and optional electric lighting and side roller blinds to meet diverse individual needs.

PC Tile Pavilion – Equipped with a high-quality polycarbonate roof that effectively blocks ultraviolet rays while offering excellent resistance to rain, wind, and snow.

Fiberglass Umbrella – Lightweight yet robust, with highly flexible, wind-resistant, and corrosion-resistant fiberglass ribs, paired with premium canopy fabric. Ideal for commercial settings such as swimming pools, hotels, and beaches.

Our in-house production capabilities cover metalworking, injection moulding, spraying, and sewing. This fully integrated process enables effective cost control, consistent quality improvement, and flexible customisation to meet client requirements.

For inquiries or more information about our products, please feel free to contact us. We look forward to building successful partnerships with you.

From this Year

Industry Experience

Production Lines

Current Employees

Factory Area

High-Precision Metalworking: Cutting, bending, welding, automated stamping, and CNC machining ensure strong, stable structures with consistent quality. Rust-Proof & Weather-Resistant Materials: Extend outdoor service life and maintain performance under various conditions. Injection Molding: Utilises high-strength plastics and composite materials with high-pressure processes for precise dimensions and smooth finishes; custom mould options available. Electrostatic Spray Coating: Delivers corrosion resistance, long-lasting colour, and a wide range of finishes to enhance outdoor performance. High-End Sewing: Uses waterproof, UV-resistant fabrics and precision stitching for durability, with optional logo customisation to support brand identity.

From material processing to finished products, ensuring complete quality control.

Sizes, colours, logos, and materials can be tailored to meet diverse requirements.

Compliant with European and American market standards, suitable for both commercial and residential applications.

Each production stage is monitored by dedicated inspectors to ensure product quality before delivery.

We will continue to pursue excellence by maintaining high standards and adopting a rigorous approach. We will provide customers with high-quality products and services.

Read More